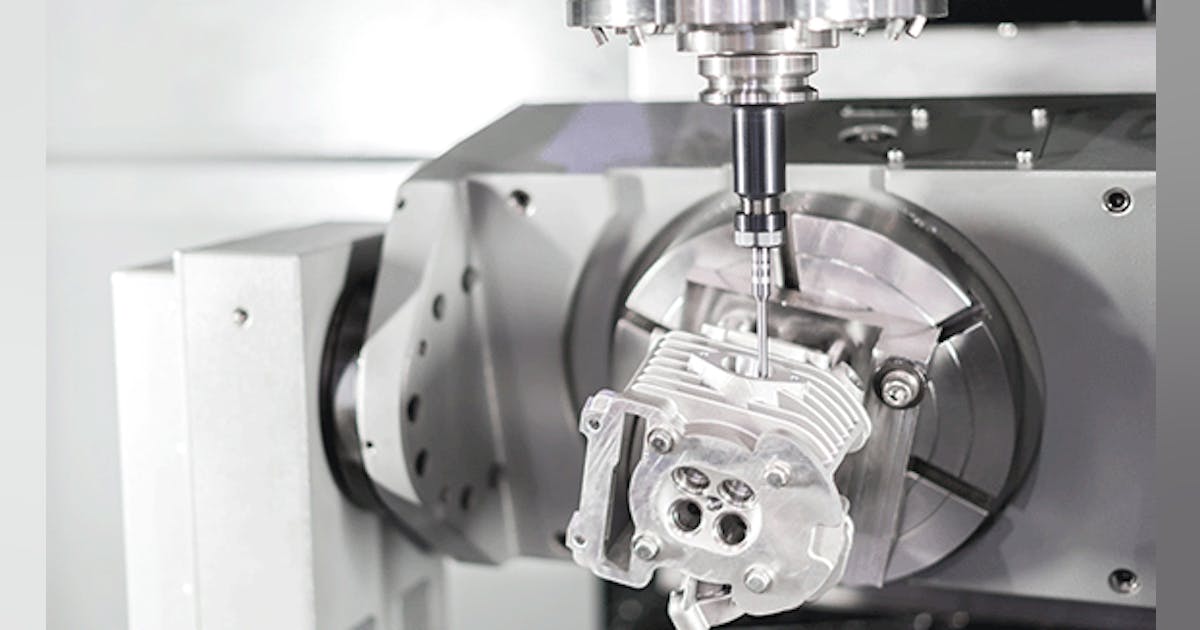

How CNC Retrofit Services Enhance Precision Machining in the USA

Unlock the Future of Precision Machining in the USA with CNC Retrofit Services. Discover how CNC Retrofit Services can revolutionize your machining processes, elevating precision to new heights. For unparalleled expertise and quality, consider hiring the industry leader, KES Machine LLC, to transform your manufacturing capabilities.

Understanding the Significance of CNC Retrofit Services

Before delving into budgeting strategies, it’s essential to grasp the significance of CNC retrofit services. CNC retrofitting involves upgrading and modernizing existing CNC machines to enhance their capabilities, accuracy, and efficiency. These services are a cost-effective alternative to purchasing entirely new CNC equipment, allowing businesses to stay competitive without incurring the massive expenses associated with new acquisitions.

CNC Retrofit Services: A Cost-Effective Solution

One of the primary reasons why CNC retrofit services are gaining traction in the USA is their cost-effectiveness. Instead of investing in brand-new machines, businesses can opt for retrofitting to bring their existing equipment up to current industry standards. This not only extends the lifespan of CNC machines but also significantly reduces the upfront capital expenditure.

The Importance of Budgeting for CNC Maintenance Costs

Budgeting for CNC maintenance costs is not a matter of choice; it’s a strategic necessity. Failing to plan for these expenses can lead to unexpected financial burdens and production disruptions. Here are some compelling reasons why effective budgeting for CNC maintenance costs is vital:

Minimizing Downtime

CNC machines are often the backbone of manufacturing operations. Unscheduled downtime due to maintenance issues can be detrimental to production schedules and customer commitments. Budgeting for maintenance ensures that downtime is minimized, leading to better overall efficiency.

Long-Term Cost Savings

Proactive maintenance can identify and address potential problems before they become major issues. This preventative approach can save businesses substantial amounts of money in the long run, as major breakdowns are costly to repair.

Enhancing Equipment Longevity

CNC machines are significant investments, and extending their lifespan is essential for maximizing ROI. Proper maintenance helps preserve the integrity and functionality of these machines over the years.

Maintaining Product Quality

Consistency in product quality is vital for customer satisfaction and maintaining a competitive edge. Regular maintenance ensures that CNC machines continue to produce high-quality products.

Safety and Compliance

Neglecting maintenance can result in safety hazards and non-compliance with industry regulations. Budgeting for maintenance helps businesses meet safety standards and avoid costly fines.

CNC Retrofit Services: A Long-Term Maintenance Solution

Incorporating CNC retrofit services into your maintenance budget can be a strategic move. These services not only enhance the performance of your CNC machines but also provide a future-proofing aspect. Modernized machines are less likely to encounter issues and will require fewer repairs, saving you money in the long term.

Effective Strategies for Budgeting CNC Maintenance Costs

Now that we understand the importance of budgeting for CNC maintenance costs, let’s explore some effective strategies to manage these expenses efficiently.

Create a Maintenance Calendar

Develop a maintenance schedule that outlines when specific tasks, such as inspections, lubrication, and part replacements, should be performed. Regularly following this calendar can help prevent costly breakdowns.

Predictive Maintenance

Utilize predictive maintenance techniques that leverage data and analytics to predict when a machine component is likely to fail. This proactive approach allows you to replace parts before they cause significant issues.

Allocate a Maintenance Budget

Set aside a dedicated budget for CNC maintenance costs. Ensure that this budget accounts for routine maintenance, unexpected repairs, and the cost of CNC retrofit services, if necessary.

Vendor Partnerships

Establish relationships with reputable CNC maintenance and retrofit service providers. These partnerships can lead to cost-effective maintenance agreements and access to expert support when needed.

Employee Training

Invest in training for your CNC machine operators and maintenance staff. Well-trained personnel can identify issues early and perform routine maintenance tasks effectively.

Regular Inspections

Conduct regular inspections of your CNC equipment to identify wear and tear. Addressing minor issues promptly can prevent them from escalating into major problems.

Track and Analyze Costs

Keep detailed records of all CNC maintenance and repair expenses. Analyze this data to identify trends and areas where cost savings can be achieved.

CNC Retrofit Services: A Budget-Friendly Upgrade

When considering CNC retrofit services as part of your maintenance strategy, it’s essential to assess the potential return on investment. While retrofitting does involve an initial cost, it can lead to significant savings over time. The enhanced efficiency, reduced downtime, and improved capabilities of retrofitted machines can translate into higher production output and profitability.

Final Words

Effective budgeting for CNC maintenance costs is essential for sustainable manufacturing operations. To optimize your CNC equipment’s longevity and efficiency, consider CNC retrofit services. For expert solutions, we recommend hiring “KES Machine LLC” for comprehensive maintenance and retrofitting support. Your CNC machines deserve the best care.